A Louisville-based company is leading the way in amazing medical breakthroughs. Advanced Solutions, Inc. hopes to provide relief for the 22 people who die per day in America while waiting for organ transplants. Advanced Solutions hopes to do so by 3D printing new organs. The local company's subsidiary Advanced Solutions Life Sciences, LLC is responsible for BioAssemblyBot, a 3D printer capable of printing biological material, and a software that allows medical doctors and researchers to visualize, design and 3D print complex biological structures. The company recently hosted a discussion with Technology Association of Louisville (TALK) where president Michael W. Golway, PE gave a presentation and led a demonstration.

TALK recently hosted the first annual Tech Fest and strives to connect the technology community in Louisville by offering free monthly talks and demonstrations. There, Golway started by giving some history related to the machine and his company, which started with just two employees and grew to 135 employees in 12 states.

"All great innovations come from the discoveries of those before them," Golway started. "...One of the first things that led to this technology was the creation of the first industrial robot by American inventor George Devol. The robot arm performed simple pick and place tasks along with spot welding and weighed over four thousand pounds. An interesting fact is that Devol was also born in Louisville, Kentucky."

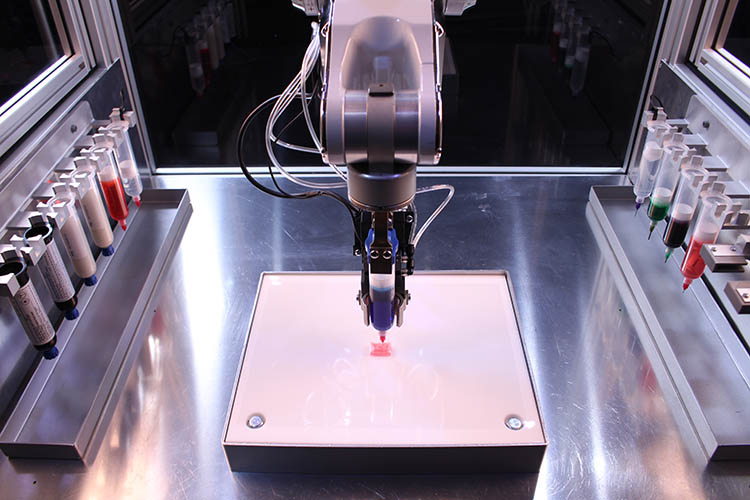

Golway's business started as a technology company serving the engineering and architecture industries. Golway toured the Cardiovascular Innovation Institute at the University of Louisville five years ago and thought that his engineering ability could assist in their research. He met partner Dr. James B. Hoying there, and they spent the next couple years combining the knowledge of engineers and biologists to create medical solutions and design the printer. They have developed three printer models since 2013, and the most recent version is the first 3D human tissue printer in the world that can operate like a human arm.

"Most printers move back and forth. The human arm has seven degrees of motion with three joints," said Golway. "The robotic arm has six joints and an end effector that can be switched out. The effector is like the hand of the robotic arm and the different types of effectors of various sizes are capable of different actions like changing the temperature of the material. The arm can 3D print, pick and place or assemble things."

Golway went on to say that effectors of the future will be able to assemble human tissues. He made it clear that the ability to reach all points of a model is very important, showing a video of capillaries being printed onto a heart model in hard to reach areas. “The machine prints models with a hydrogel and then inserts cells for incubation. As the cells grow, they take the shape of the gel model which then biodegrades.”

A video was also shown of a model capillary system being printed to demonstrate the very minute size of the detail that can be printed as Golway explained that printing organs is a long way off. The world is currently only at the stage of printing cell systems, but it is advancing quickly. The software for the BioAssemblyBot is called Tissue Structure Information Modeling (TSIM); it empowers medical doctors and researchers by allowing them to import common medical images like MRI’s and CT scans for 3D modeling, giving them freedom to explore arrangement of cells and create models.

"It is the next step in drafting," Golway said. "When I was in engineering school, we used drafting desks to draw lines, arcs and circles. Then, we used software to do it. Now we can attach data and create 3D models. The idea is to give non-engineers the ability to use it."

"I'm not an engineer," added Dr. Hoying. "I sat down at the computer and was able to do something in 20 minutes that usually takes us five days. That's invaluable."

Technician Kyle Eli ran a demonstration as Golway explained that syringes are loaded with living cells before the machine prints material. It can print with nine different “bio inks” simultaneously, switching them out as needed. Everyone excitedly gathered around to watch the arm print a heart valve model. As the demonstration continued, Dr. Hoying showed a rendered model of a cleft palate in TSIM. He explained that they are also working with the University of Louisville's School of Dentistry to create solutions for this devastating condition.

"Currently, a piece of bone from the child's hip or leg is taken and ground with a dremel tool to create an appliance to try to fit it into shape needed," he explained. "Imagine being able to 3D print an exact fit made from the child's cells that would grow with the child. Orthopedic bone material is probably going to be the first successful application of printed organic material, because it is easier to create than complex living organs."

The technology is currently used mostly for research and lab testing purposes. None of the printed materials or devices have been implanted in humans yet as they await FDA approval. Dr. Hoying added a final thought provoking statement about the potential uses of the BioAssemblyBot.

"When a child is born with a hole in their heart, we currently use a plastic patch to fill it. The child may need additional surgeries as they grow to replace the piece. Wouldn't it be great if we could drop in a patch made of their own cells that would grow with them?"

Photography: The BioAsseblyBot arm in action. Provided by Advanced Solutions, Inc